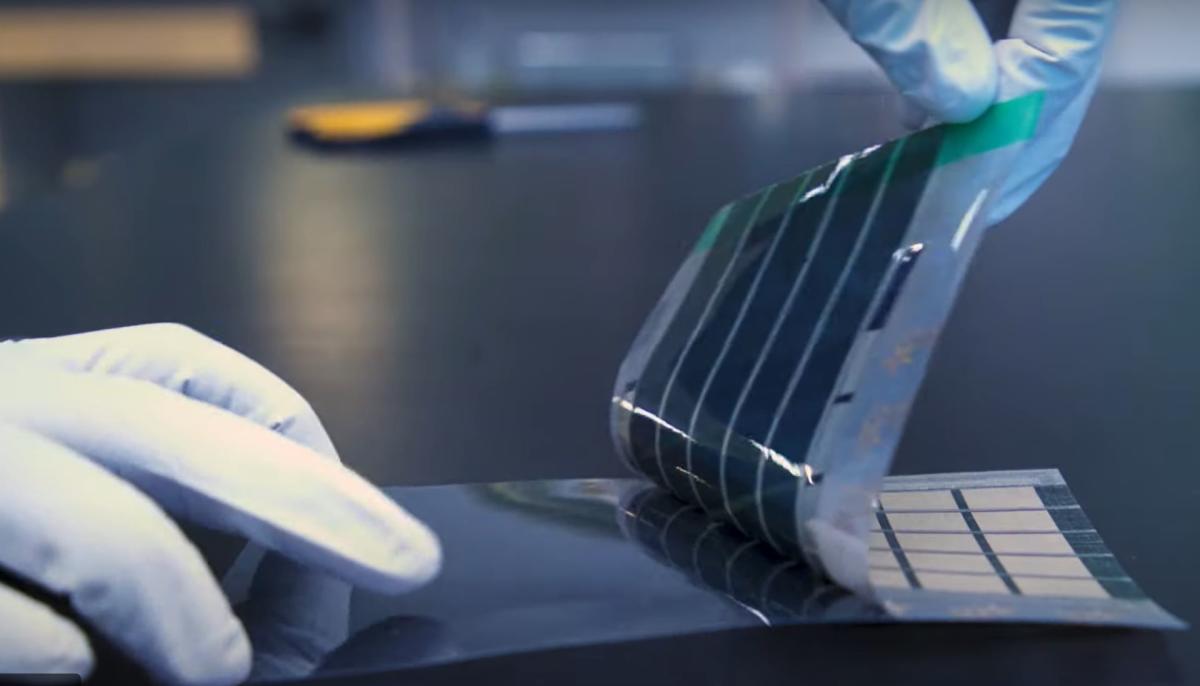

Scientists develop mega-thin solar cells that could be shockingly easy to produce: ‘As rapid as printing a newspaper’::These cells could be laminated onto various kinds of surfaces, such as the sails of a boat to provide power while at sea.

If it’s shockingly easy to produce then just do it and then you can write a declarative headline that doesn’t need to use the word “could”. If you can’t then I’m guessing it’s not that shockingly easy.

I mean, even if it’s easy to do, that doesn’t mean a manufacturing process is easy to ramp up. You need equipment to produce it, and people to do it. Logistics of that isn’t like just turning on/off a light switch.

Some people have never tried getting a product to market before, and it shows.

I would wager most of us haven’t.

I don’t care what you say the am/fm butt plug was going to be revolutionary!

At that point, you can just call it bm radio

Without headlines, no investors. Without investors, no equipment. Without equipment, no product. Headlines like these drive investment.

I love shows like How It’s Made, you get to see the Rube Goldbergian systems that produce stuff we take for granted.

Yes, exactly. My point is that I’m tired of these bullshit headlines that are implying that we have some great breakthrough; unless the discovery also accounts for everything you listed, it’s not a breakthrough and we, the public, don’t need to hear about it just so that a newspaper can sell clicks and ruin trust in science.

You seem to be conflating breakthrough with manufacturing capacity

No, I’m just not referring to a slightly novel manufacturing process that will probably lead nowhere as a “breakthrough”.

Some of us like learning about science and technology, if you only want to know about products then watch adverts.

The average person understands the difference between ‘will’ and ‘could’

To echo the other individual who replied, it’s shockingly easy to make injection molded parts, but there is usually a long process before you bring the final product to market. And that’s with all the manufacturing processes already existing at scale.

In this case, the processes need to be fleshed out from scratch, which adds even more time to the ramp up. So even if the headline is 100% accurate, and there are no other roadblocks, it would still take a significant chunk of time to bring to market.

Time, money, man hours, etc, etc. All while still figuring out how to make it at scale and be able to sell it a a price that enables you to continue the business.

It’s hard stuff, for sure.

Yeah, how dare they report on science and technology - I’ve barely seen a dozen articles about Will Smith’s personal life today, we don’t have resources to waste talking about successful research projects from MIT!

When MIT get in a salacious romance scandal then they can have a bit of our precious media space but get the fuck out of here with your science bullshit nerds.

For a while I was celebrating when I didn’t see Taylor Swift’s name in either the sports or entertainment heading on google news. And each heading only showed three headlines.

This isn’t science, this is engineering, and it’s crappy engineering at that.

“mega-thin”? Is that like “micro-large”?

Pepperidge Farm remembers when journalists had a grasp of the language.

They should have just used “hella-thin”.

Or “wicked thin” for the New England audience.

THINTACULAR!

THINTROCIRY!

AM I DOING THIN RIGHT?

Thintastic is quite good also

Lol I thought the same thing on first read. Then again “micro thin” sounds redundant…

“It has a large amount of thinness” Mega-thin is fine lol. I do like hella-thin though

Thin. Very thin, paper-thin. Ultra-thin if you want hyperbole.

What about jumbo thin

This kind of affordable tech has been promised as “about to hit the market” since 2003. I’ll believe it when I see it on the market.

Since 1975, which is as far back as I can remember with this stuff.

I’m sure my parents would say the same.

bro i can run LED lights by putting wires inside my body

Kinky.

was thinking the same thing. this printing press solar has been demoed and showed off for literial decades. and yet it just never seems to materialise in any meaningful fashion.

This has its own applications but I can’t say I’ve ever heard anyone complain about thickness of solar panels. Efficiency, power generated, etc. Sure.

I don’t think it’s so much about thickness, but being super thin presumably means it requires less of a manufacturing process and also less raw materials. Could bring costs down on panels and make them more financially viable for projects.

On top of that, could make them viable for other surfaces that might not have been a good fit for them with current tech

Indeed, 44 lbs for an 8kw installation is very light.

Although the cells can only generate half the energy per unit area compared to traditional silicon panels, they can generate 18 times more power per kilogram, Fast Company reported.

For most users, I’d guess that unit area is more important. But for satellites, I suppose that as long as they can unfold, space isn’t really an issue. You’ve got all of outer space to spread out into. But weight determines a lot of the cost of putting the thing up in space, so you’d like that to be low.

If they’re cheap enough, you can just slap them on any available surface that gets a marginal amount of sunlight. Doubly so if they’re flexible.

If you can print them on textiles they can literally be everywhere.

Weight does play a huge role for satellites and to be honest I have very little knowledge of solar panels they use. However since solar sail is a thing, I’d argue surface is indeed a factor with satellites. But perhaps they managed to get some use there. There might be even other use cases I just didn’t think about. My original comment was mostly pointing out that thickness was rarely as big of an issue as it was efficiency.

For anything other than house roof solar price per kw is going to be the deciding factor. Rural land is very cheap compared to solar panels - we’re talking about a 100:1 cost ratio.

Also I can’t imagine you’d want to add too much extra weight to a skyscraper

Use cases increase if they are thin. Instead of limited to rooftops. For example, take a look at what Aptera is doing.

Burning investor money on a DOA meme product just like Lightyear One did?

Ooof

Clearly you’ve never

owned an air fryerwanted a solar powered car. Or imagine shipping containers covered in these powering the trucks that haul them! Or trains! Even boats. Basically any kind of self powered transit, especially ones with greater surface area.Second edit: Another idea! Clingfilm solar panels for windows, or blinds and curtains that can power the lights!

Or wind turbines skinned in thin, light, flexible solar panels. You’d double dip on energy per square meter. You could have a solar farm on a stick that also makes wind energy.

If you dream of covering a vehicle with panels and have it driven by that power, I have to burst your bubble. That’s not even nearly enough surface to generate enough power. Perhaps assist in trickle charging battery, sure. But we already have flexible panels, even self-adhesive ones. And again, their biggest downside is not their thickness but efficiency. There will never be a self-propelled vehicle. Just a nature of things.

As for window blinds, etc. There is already glass that lets enough light through and can generate electricity. Those are even worse when it comes to efficiency due to non-ideal angle, light passing through, etc.

“We already have technology that doesn’t do those things well enough, so this new technology that won’t see advancement ever has no chance of addressing these issues either.”

Trickle charge is awesome. Trickle charge the semi during your 8 hour driving shift and then another 8 hours while the trucker is asleep. If that nets half a charge every other day, that’s a charge and a half a week. It’s not self powered like a perpetual motion device, those aren’t real. But regenerative braking is a worthwhile addition to an electric truck. Why wouldn’t solar paper or whatever we want to call it also be part of the solution?

More like, it would take 8 days of constant sun to have an hour of driving.

Currently. Technology gets better

No, there is literally only so much energy radiated by the sun in a certain area. The number of square feet of roof on a car is just too small to propel it, even with magic theoretical 100% efficient panels.

You do know cars don’t have to move all the time right? If I was on a road trip and got stuck because of no juice for whatever reason, I would be able to camp wherever I am for a couple days and then have enough to move.

Your thinking is pretty small minded

As outlined elsewhere in this thread, you’d have to move the Earth closer to the sun for this to be feasible. You can only get so much solar power as it stands, and even 100% efficient panels would only go so far.

Nah. Even 1% power is better than 0% power

There are physical limits at play to how much power this can provide. No amount of technological improvement can break them.

Imagine the driver plugging in the truck during the 8 hours while they’re asleep. That’s an achievable goal.

Here’s a video of a camper van with traditional solar panels on the roof using a slide-out awning technique.

https://youtu.be/Ev5C9gf0zFc?si=97piy-3mV9TIsRlu

You might say that’s impractical for regular use. Sure, it is, but your previous argument was that is was impossible due to physics, which the video clearly shows isn’t physically impossible, so we’re already much closer to a reality. I’m not saying it could drive forever without stopping or be the only power source. That’s silly. But if it reduces the need to charge from a grid by X% it can be a useful technology. Go on now and tell me how it could never ever work.

A camper van. Which has electrical use for things besides turning a motor. Yeah, that’s useful, but it doesn’t exactly help your case.

Under optimal conditions, the sun gives us 1000Wh per square meter. Let’s say you have a 100% efficient solar panel. A semi truck trailer has a max of 42 sq meters on top of its trailer. So you get 42kWh out of this.

It takes about 280kWh to keep a semi truck at cruising speed on the highway. Thus, in this most optimal scenario, it would give you an additional 15%. Even this assumes there is no additional aerodynamic drag from the panels, mounting hardware, or wiring. It wouldn’t take much to completely blow that 15% away.

If it’s a cloudy day, all of it is now deadweight, and now hurts more than it helps. If you don’t drive on the equator, its output drops and it now hurts more than it helps. If you have solar panels that actually exist that do around 20% efficiency instead of 100%, it now hurts more than it helps.

I guess we could move the Earth closer to the sun. Won’t help our global warming problems, though.

It also turns the motor bro, did you watch it?

solar farm on a stick

Also known as a “flag”

Ha! That could be it too, but I had meant more like a wrap around the pole.

Those all sound like efficiency issues still. Covering any form of transportation with solar panels is primarily pointless because of how little power that would generate. Even if you covered every available inch with the most efficient panels invented, it would take over two weeks of sitting in full, direct sunlight to charge a solar-powered car, which you would drain in four hours of driving. As these panels are half as efficient as traditional panels, you could drive maybe

atwo minutes per hour you sit in full sun.Where are you getting that two weeks number?

A car has up to 55 sq. ft. available to panel. A good solar panel gets maybe 20 W/sq. ft. efficiency. An electric car has around an 80 kWh battery. A day has roughly the equivalent of 5 hours of full sunlight.

Then you just multiply/divide everything together, and you get 14½ days.

If it takes 14 days to charge the battery, you just need to use it less then a 14th of its range per day and this all becomes very feasible, no? First link on google tells me high efficiency EVs output 6.4km per kwh. That’s 30 km a day at 80kwh, nothing to scoff at in my opinion, although its probably less.

I also think it could become popular to lengthen the in between charging times with higher capacity batteries.

+1 for the use of wolfram

Then factor in the extra cost of the panels and connecting hardware. The ones mentioned in OP are supposed to be dirt cheap, but they’re also half as efficient. The tradeoff cancels out the benefit.

Also, this won’t help highway driving much. EVs have already solved city driving just fine. 100mi range will do, even without good charging stations outside your home (with caveats for apartment dwellers). Highway range is where we need improvement, but you can’t ask people to just drive for 1/14th of the day there.

Fair enough. That definitely is true for a car. I would wonder whether the power/surface area/weight/energy consumption all scale linearly or if a vehicle like a semi with more surface area could take advantage of increased number solar panels, or would the amount of work needed to move the larger truck scale equally to the power gained?

Thank you for your proving reasoning for your opinions and sources. You’re groovy. Don’t feel like you have to again for this random thought of mine unless it’s enjoyable for you as part of our conversation.

Wait, what the fuck, dude. I had given you the math for semi trucks two hours before you posted this. You already had those numbers, and yet you speculate otherwise here.

That guy isn’t being a dick. You’ve got a bad attitude and I don’t like talking to you. Goodbye.

Gotta be useful during the zombie apocalypse though. No more raiding gas stations and broken down vehicles.

First, the thickness factor plays into flexibility. Just imagine surfaces of every shape being covered in solar cells. Flexible panels could also be less prone to breakage.

Second, with “as rapid as printing a newspaper”, this might be a major cost-reduction thing, even on top of the process needing less high-pure Si material.

This might make solar power generation more attractive even if the efficiency would be lower than other methods, because this would drive the ratio $/kw down.

Kind of like these? Flexible solar panels are not a problem. And no, being newspaper thin will never be stronger than mounted on rigid surface. If it bends it has a definite limit in number of times you can bend it.

As for “printing a newspaper” and rapid production, when I see it I’ll believe it. At the moment it’s nothing more than speculation as they themselves have not made it yet. Every manufacturing process starts slow and then speeds up as process is optimized. The problem is whether there is a financial incentive to start producing in the first place.

By “flexible” I did not imply “use it as a hinge”. It was more like: “you can install it on a non-flat surface”, e.g. by gluing it down. Now that surface would provide the needed overall stability. Imagine having you cars roof and engine hood being completely covered in solar cells - or basically be a solar cell. No, you would not be able to drive it as an EV with the amounts of power provided, but it could trickle charge a battery, or power a fan in hot weather so the interior will not be boiling when you return to your vehicle after a day at work.

We already have the panel type which is glued on. But I guess it remains to be seen whether there’s a financial incentive to mass produce this.

Indeed. Price is the key issue.

Bulky, heavy, stiff, …

Which would all be a valid concern if you had to carry them all the time or bend them. There are flexible solar panels which you can glue on roof of your boat or car though.

AFAIK this was previously developed about 5 years ago in Australia at the University of Newcastle Engineering Dept.

Not sure why this lot n the US is claiming credit for it.

https://www.newcastle.edu.au/newsroom/featured/public-debut-for-printed-solar

It’s a different process. Multiple processes with varied applications are absolutely essential to making this style of solar the norm

It’s a great thing that this particular field continues to see innovation.

New process

Scientists used electronic printable inks, using a technique similar to how designs are printed on t-shirts. As these thin solar cells are difficult to handle and can tear easily, scientists searched for a lightweight, flexible, and resilient material that could adhere to those solar cells. The fabric they chose was Dyneema Composite Fabric, a material known for its incredible strength.

After printing the electrodes on a flat sheet of plastic, they glued the sheet of plastic on Dyneema. Lastly, they peeled away the fabric, which has picked up the electrodes, leaving a clean sheet of plastic behind.

Your linked process:

The organic solar cells being deployed have been printed on laminated polyethylene terephthalate (PET) plastic by a printer formerly used for wine labels.

The 18 metre long ultralight and ultraflexible strips are similar in thickness and appearance to a chip packet, the university team have said.

Ok thanks. I see the difference. It was a late night knee-jerk defensive post.

The fabric they chose was Dyneema Composite Fabric

As a fabric geek with a cut/sew shop working on marine canvas, this gives me a raging boner. The panel making process might be cheap but I’ll tell you dyneema fabric isn’t. Bet there’s great mark-up on it though! 🤑

We do love “discovering” other peoples things and claiming they’re “the new _____”

An Edison tradition.

Man, y’all a bunch a grumpies.

This technology doesn’t hinge on what we here believe or predict. It will happen or it won’t.

We could speculate on how cool it would be, and how it could be used if it happens, instead of pooh-poohing it.

I’ll believe it when I see it.

You guys realize that this is a significant step towards having moving pictures like in Harry Potter right?

please elaborate

And then we never heard of this miracle technology again

If it’s true you can print it on cloth, and it has reasonable longevity, sailors will be buying the shit out of it.

I like them thicc

I would imagine it could only be useful for 30 minutes before the cell would be unusable. Arent solar cells just P-N junctions where if it is really thin it would just run out of holes to fill?

Edit: why am I being downvoted? To my limited understanding from my electrochemistry courses from 10 years ago, photovoltaics depend on the density. Theres only a limited amount of free electrons and only a limited number of free holes. The thinner the material the less likely an electron hole can get filled with whatever N-doped semiconductor used.

By your logic all solar panels would run out of these holes after a certain period of use?

They might be right for other reasons though. I once worked at a lab where they were doing r&d on this sort of thin solar cells, and their stability and longevity was the #1 biggest problem. They worked great inside those anaerobic box thingies in the lab, but they degraded to nothing very quickly upon first contact with real atmosphere.

Yeah but that’s experimental tech. OP’s talking about limitations on normal solar panels

Im talking about limitations of thin solar cells largely. I think there is usually enough doped material in regular cells that it usually isnt looked at.

Yes, correct me if I am wrong buy is that not the case?

No, definitely not. There’s no such lifetime limit.

Why not? I have not looked at this in forever so im probably wrong but I thought that these pn pairs end up creating some band gap. Over time that band gap widens until the energy from the sunlight just isnt strong enough to move through the system. In the end, it has a finite qty of holes so that limit depends on the qty of doped materials.

Again i dont remember well so 🤷

You’re a bit jumbled up here.

There are P N junctions where the magic happens. The P side conducts by moving vacant electron “slots” through the structure, we call these holes as in electron holes. There isn’t a lack of electrons or anything, both N and P are charge neutral, instead: Where in a metal if you push an electron into it in a circuit it bumps another one over a bit and so on in a P type you pull an electron off one end, the “hole” moves taking an electron from deeper in to fill where it was until at the end it pulls another in.

As you can see the number of holes is constant under normal circumstances. We pay attention to them for reasons that’ll become clear.

Now since N types want to volunteer electrons and P types have little electron holes ready, and these are negatively and positively charged (remember overall the material is neutral though) if we put them together then in a very narrow region some holes will accept electrons and fill up. As this happens ion cores (nuclei of the atoms making up the material missing an electron) are exposed in the N type making a small positive region, while the extra electrons in the P type make a small negative region. This balances the hole-electron attraction exactly and we have a stable charge depleted region.

Following? let’s talk about lightning for a moment.

you know how everything becomes a conductor if you try hard enough? think lightning jumping down through air, a tree, and some literal earth. Well lighting ionises (pulls electrons off making a kind of gas made of charged particles) stuff mostly but there’s a special sort of state most metals and similar can get to (indeed most metals are in this state at room temperature) where they’re sort of lightly ionised. Instead of the electron going away it sort of becomes promiscuous and is happy to share its time with nearby atoms.

Electrons in this state have certain energy levels associated with them, we call this band of states the conduction band. To get to that energy state you need to go from the valence band across a "band gap " to be promoted to slutty electron.

OK so these bound hole-electron pairs moved from the conduction band to the valence band when they settled down with each other. They can’t conduct anymore. But if a photon hits them just right they trial an open marriage and separate into the conduction band. The electron is now more attracted to the positively charged region back from whence it came and visa versa for the hole. Once they get bumped over they have to go the long way round the circuit to find each other again and that’s how we get energy.

Thank you for the eli5 on how PN junctions and band gap works.

All I was saying was if there is some N-type material with only some finite number of excess electrons and some P-type with finite number of holes, there is a specific energy level that this semiconductor requires for valence band conduction. The electrons are not being replaced in the circuit so the N-type is slowly degrading. In a normal scenario, these materials would take forever to deplete and so it is usually treated like an infinite well. In reality, a cell will have only a finite potential energy and a discrete so in effect widens the band gap until the cell is no longer functional.

On the contrary, i know thin film solar cells exist. Way back in college i remember making organic dye sensitized solar cells and they were complete garbage. I might be associating all thin cells the same way but yeah. Was a bit of time ago for me and im going off my shitty memory

The electrons are being replaced, otherwise the system would become charged over time. They go the long way round the P side of the junction and bond with a hole again in the depleted region.

Solar cells do deteriorate over time but it’s not due to use, or not directly. The structure of various parts gets damaged through lattice migration due to heat/thermal cycling, UV radiation and higher can cause excitation to reactive states that damage crap, dopants can migrate around over time (like how carbon can leech from steel) and reduce the conductive efficiency etc.

I think this might be what you’re confused by? there are a finite number of available charge carriers in the depletion region and damage to the region uses them up, but it’s not because they’re used up it’s because of structural and chemical changes caused by damage that occurs due to the environment.

I too have a bridge to sell you!

I love when people act like progress never happens, we’re in a world where developments happen so fast it’s impossible to keep up with a single field of development because so much new stuff is happening but sure anyone interested in the emergence of printable pv is a rube…

I see the same in ai discussion, I use it when coding all the time but every article about a new development has someone saying it’s useless and a gimmick.

Rapid deployment solar is happening whether you like it or not, the science has been building for a couple of decades and every interesting new study and development opens up new avenues of possibility. This will be a game changer in many situations and it’s something we can see getting closer, studies like this are so interesting because we can see which avenues things are likely to take and consider how it would affect things.

We have a tendency to think of science as someone waking up and inventing something and then it’s ready to hit the shelves but it’s never worked like that. If you’d been reading the news when photography was new you’d see endless news stories about progress towards colour photography, about potential methods and means of a making a single plate colour image - famously you’d have also seen discussions in the letters section of the Times between some of the chemists that’d go on to actually solve it.

Progress happens, science happens - sure you don’t care that they found a way of transferring printed solar onto fabric which avoids the need for the fabric to be able to endure the entire fabrication process but it’s actually a pretty cool thing. The article is kinda dumb I really don’t think this process will hold up to the intense sea air and mechanical stress of being a sail but for simpler uses such as an awning cover over carparks or even better train lines its likely to be very useful - imagine being able to generate the power for electric vehicle charging or train travel simply from a fabric roof which also shades the area from hot sun.

A process that makes the current chemistry cheap and fast to print onto a useful material is a big thing, not as huge as extending the working life of the materials but by being easier to make and replace we might find that there are a lot of uses for rapid temporary deployment of PV in situations like disaster zones but also in seasonal infrastructure which is especially important for things like music festivals, holiday locations (which see power usage vastly increased when tourists are in town), and travel routes.

It can be as plain as “we literally couldn’t do this last week” - like when we invented grass that doesn’t need to be watered - and people will be there to tell you it’s shit and you’re incompetent if you feel otherwise.

Yeah, you’re missing the point that this is a shouting headline that I’ve read about 50 times in the past ten years at least. Progress happens, I’m sure, I neo t say it doesn’t. This, however, is sensationalist bullshit, not progress.

I think you probably don’t understand the article because you only read the headline, the actual study is very interesting and solves a problem that was often talked about before. Those of us with an interest in this field recognise the advancement that’s been made are are interested in the implications,

The headline is like if every article about CERN, James Webb, and any other physics study was titled ‘could lead to unified field theory’ or if every time anyone releases a new machine learning model the headlines were all about AGI - Oh yeah, they do that one too…

So yes it’s a bad headline but it’s great science and we really are making great progress with printable PV - there will come a time where you start seeing it everywhere.

Much like AI people have known that the relevant breakthroughs have been coming for a long time but it’s not until a certain threshold is met that we see companies scrambling to stake their claim. Someone will make a factory producing one of the various printable PV methods and market it to a suitable situation, people will find other uses for it also besides the initial market and as demand becomes established others will leap on and start making their own variation.

What? Newspapers not rapid. They are printed only once per day because of all the writing and editing that’s required. Do it any faster and you’ll end up with lot’s of typos and factual errors.

The printing is fast.

Yeah, but do you want to be the person who has to fact-check every photon that hits these solar cells? I’m sorry, but a lie can radiate from the surface of a star and power your vehicle before the truth can even put its shoes on.