*Laughs in American*

*sobs in americsn*

Why are we so backwards?

*Laughs in American*

*sobs in americsn*

Why are we so backwards?

I’m curious.

What’s your line of work, if you don’t mind?

Don’t tell the boss, jerk.

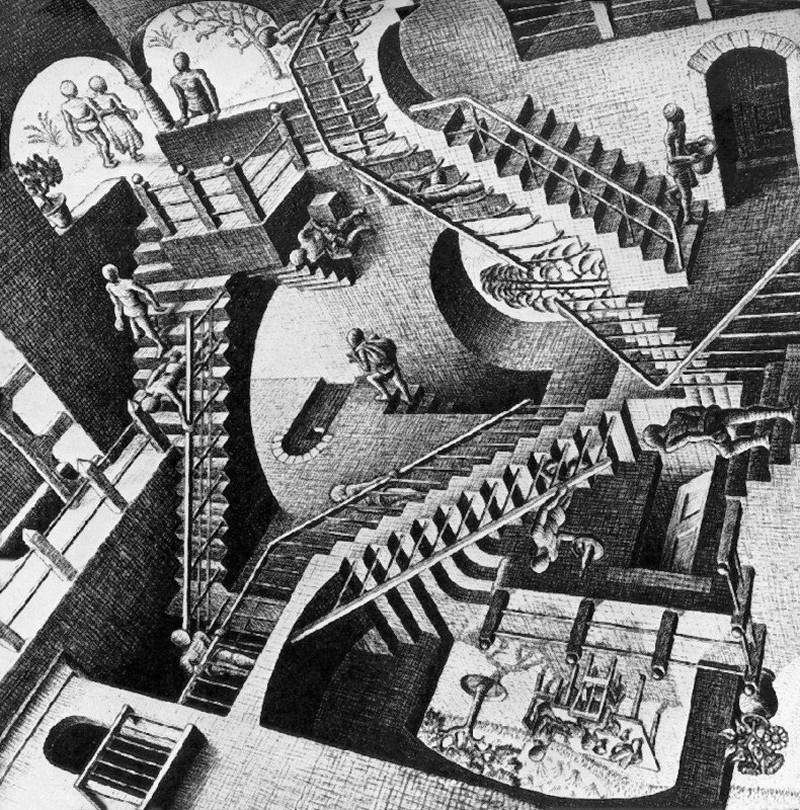

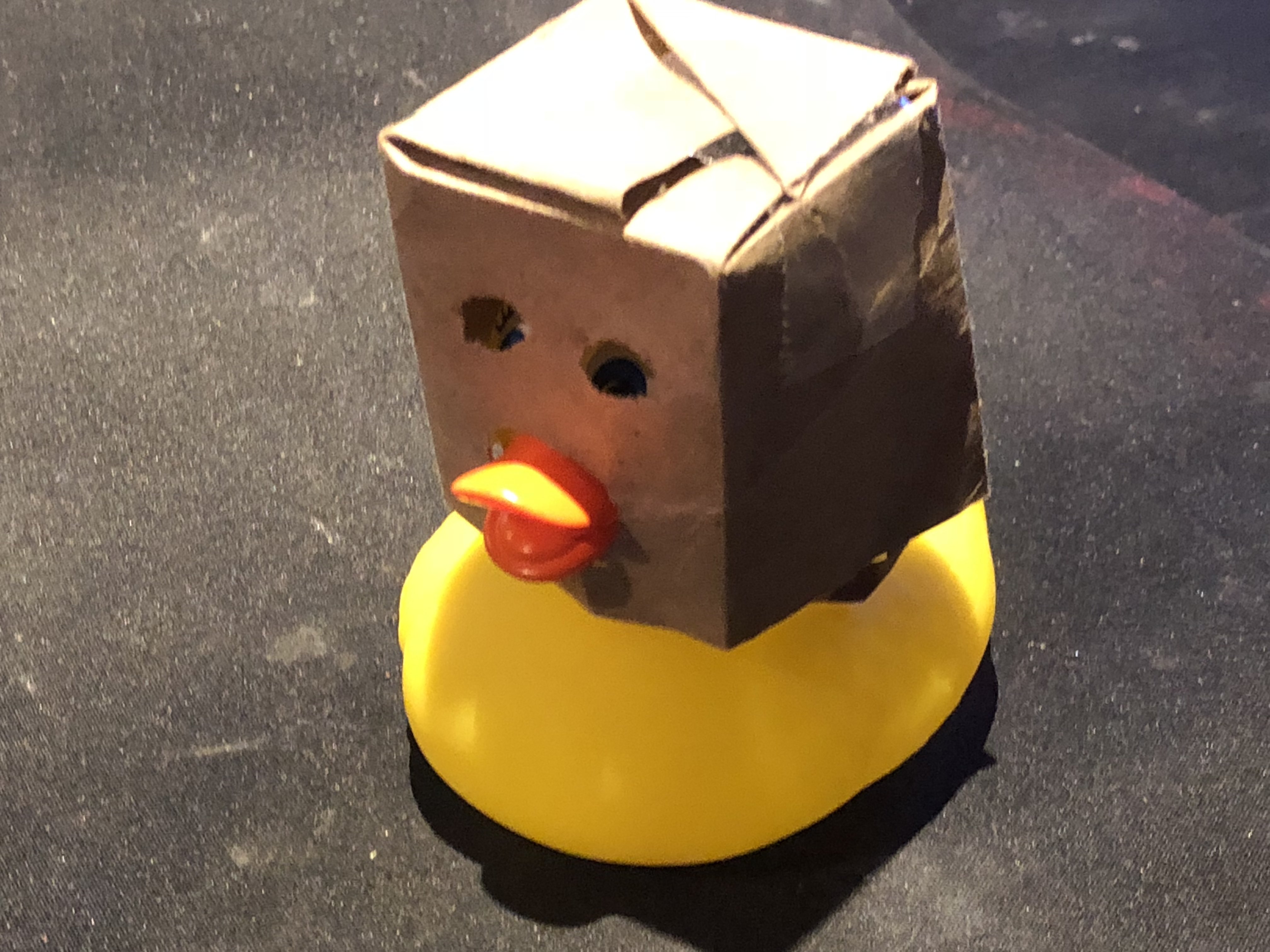

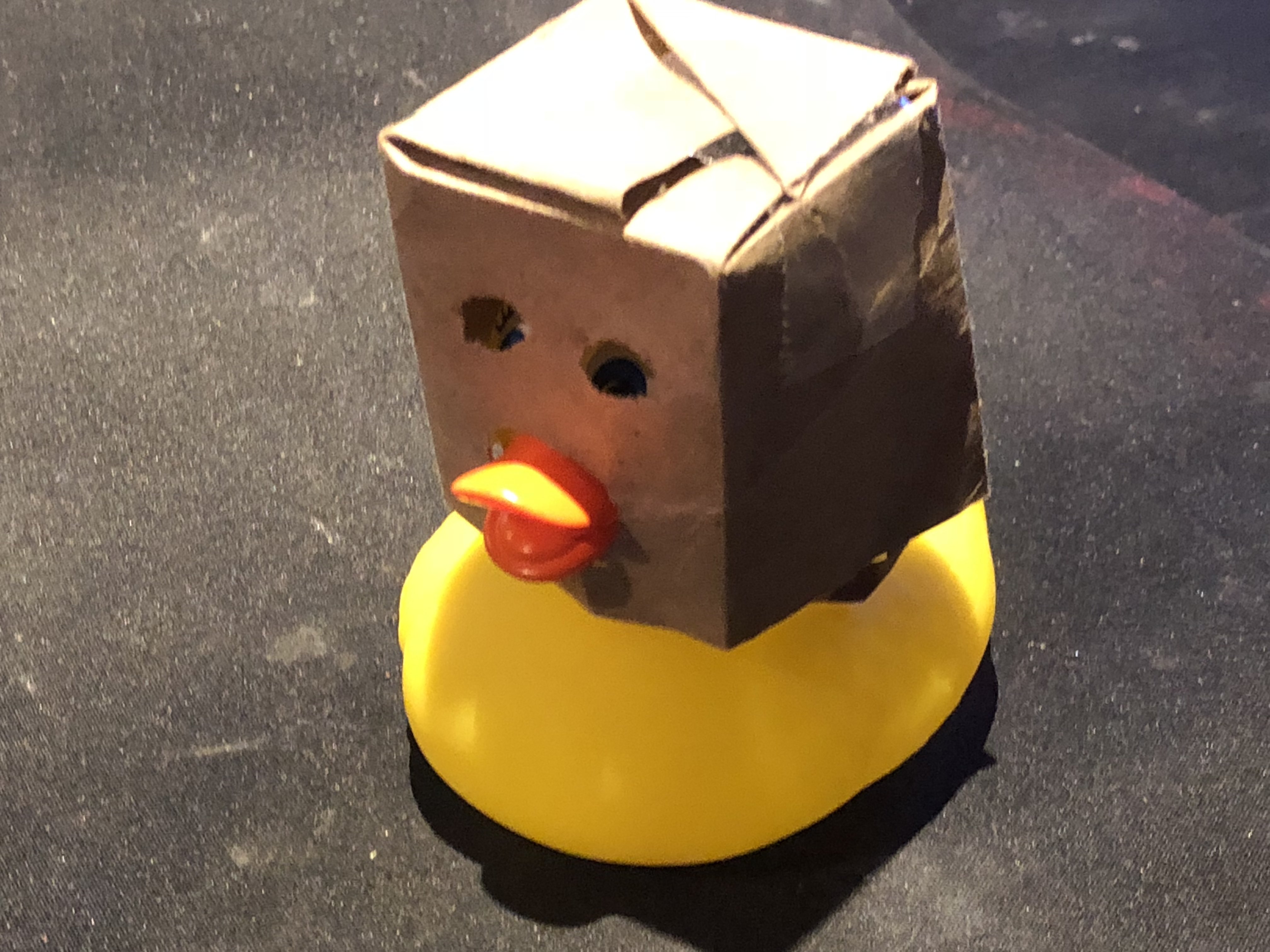

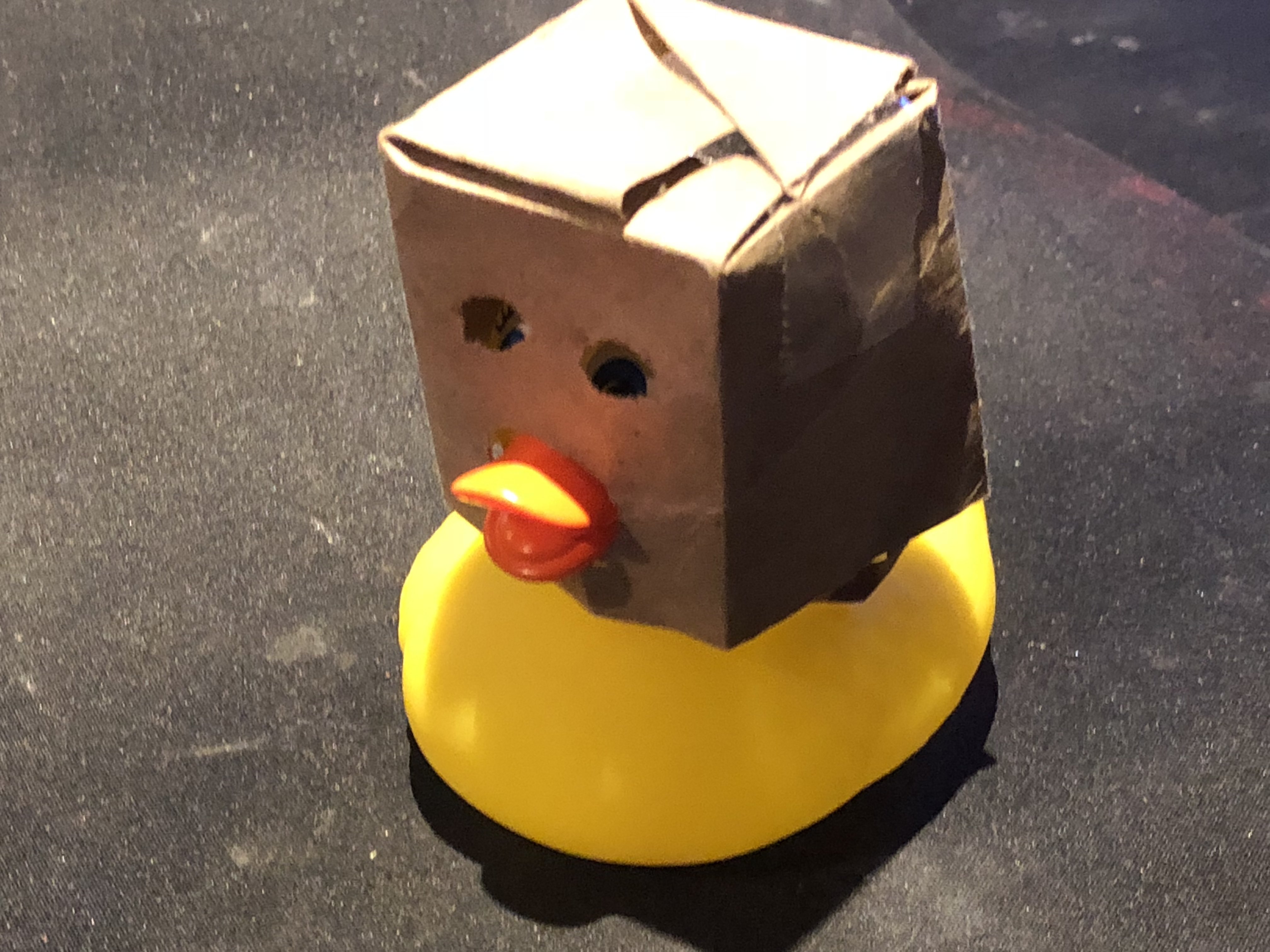

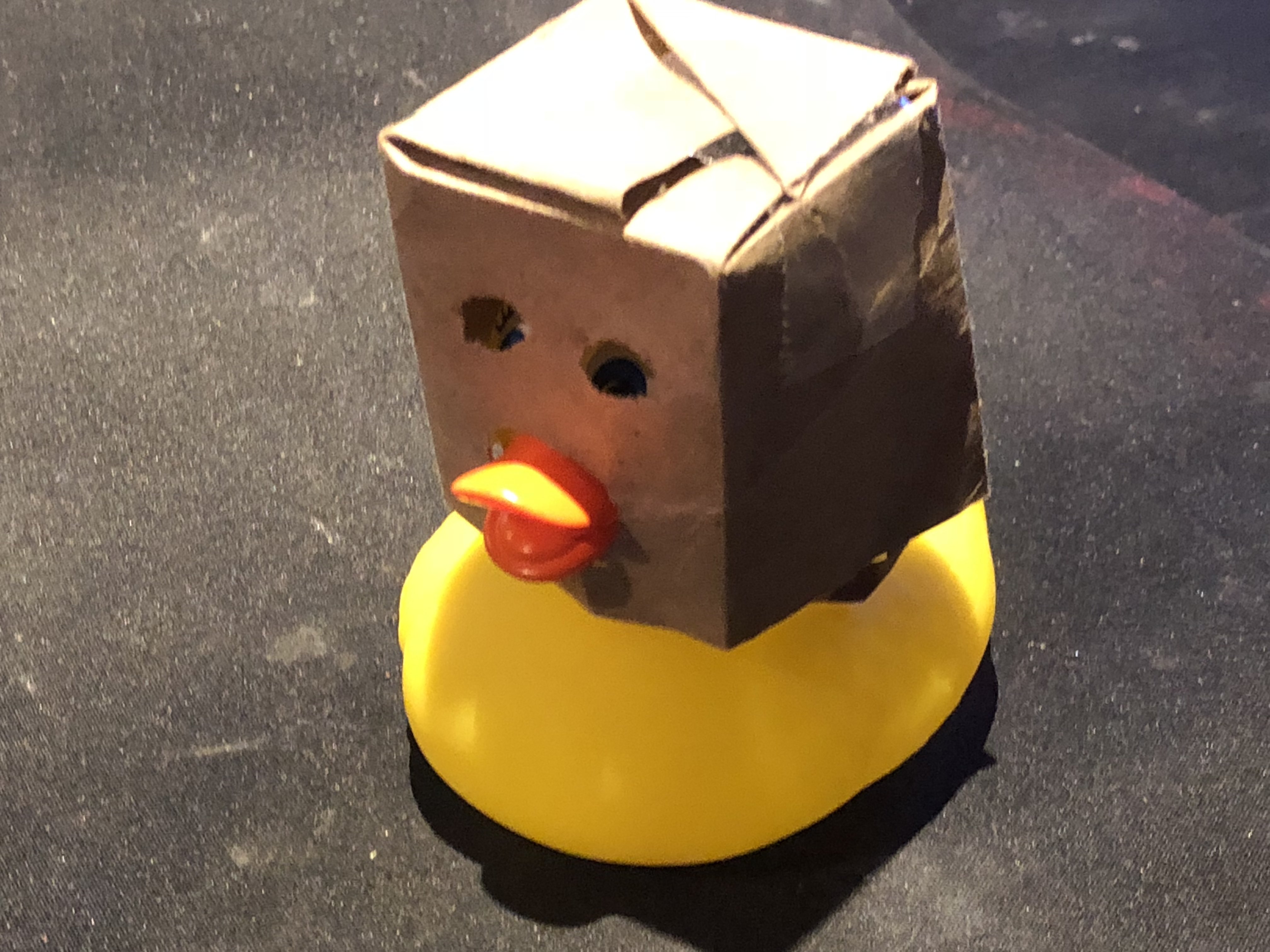

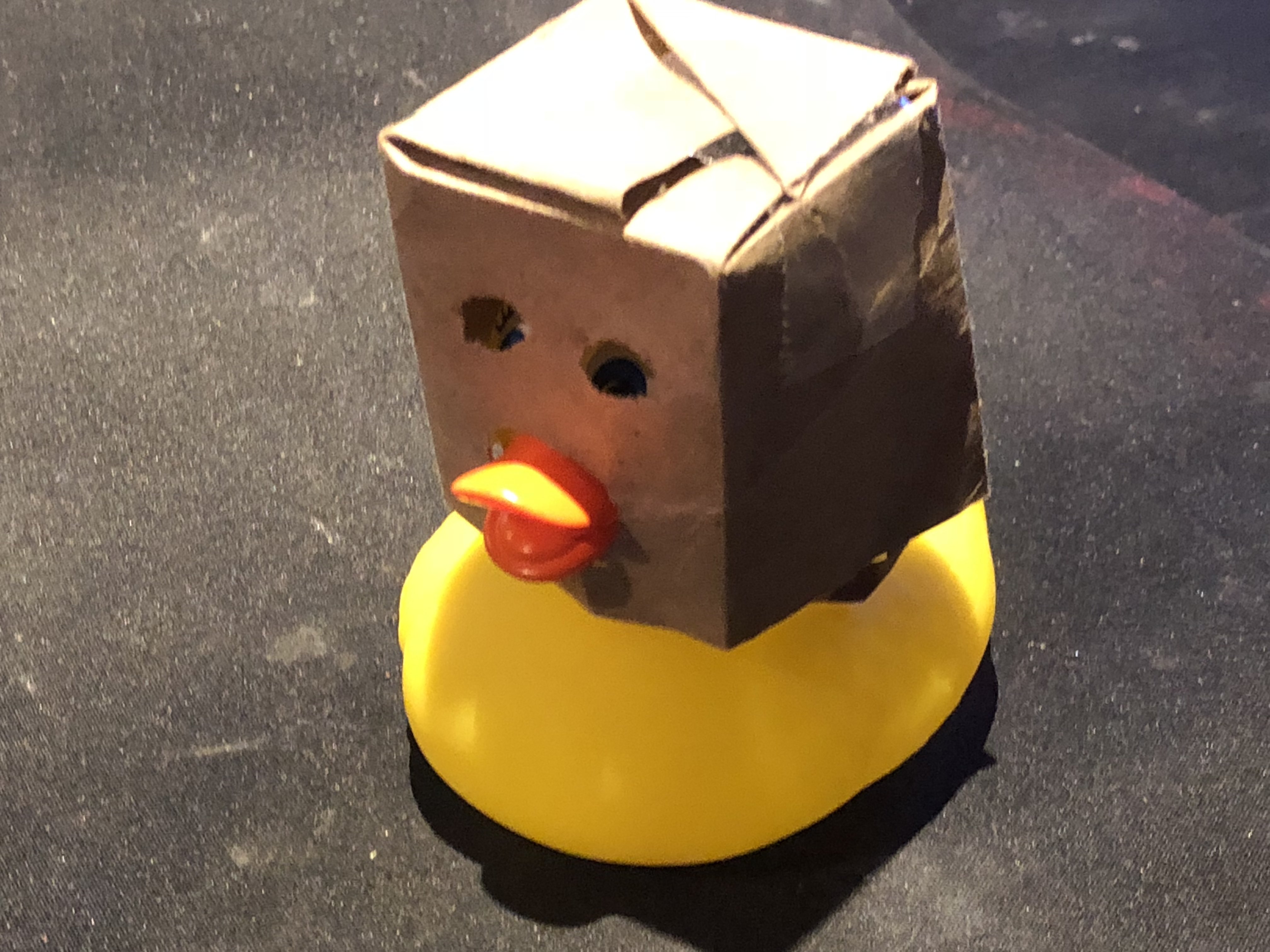

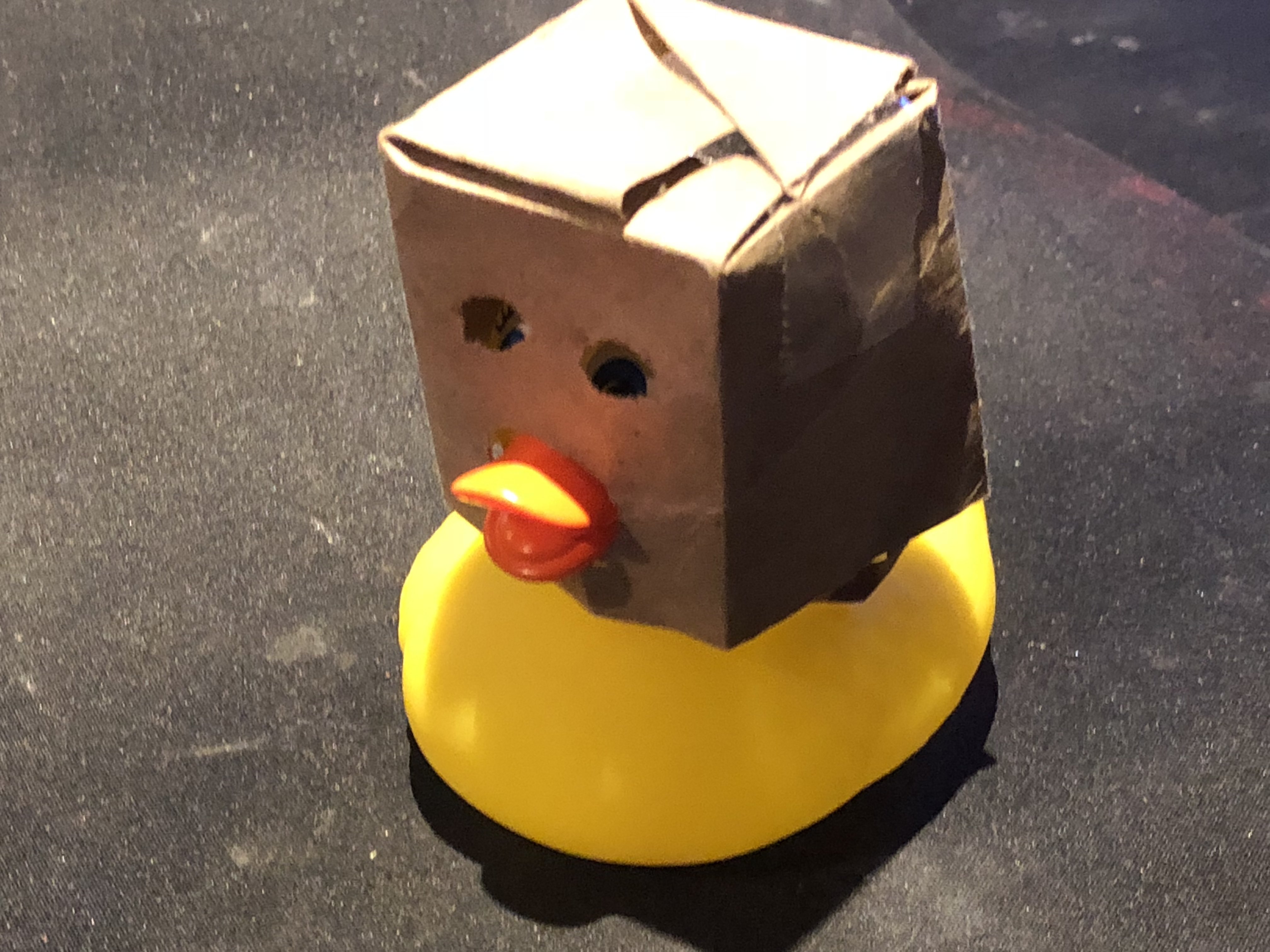

I was kinda referring to the impossible shapes and dimensional illusions Escher used. Like this one:

I kinda like escher’s work…. And this is giving off those vibes…

definitely a nerd’s nerd.

This is why I named my strain “Golden Kubernetes”

keep the server farm in front of the weed grow. they’ll lose interest. (as they say, business in front, party in the back. Just not for hair.)

Yes. The nozzle.

The one part that puts a consistent pattern into the filament as it extrudes that can be corrected for variation from temps and materials and whatever else.

Unless you’re printing abrasives, your brass nozzles doesn’t wear that quickly and defects from the boring out during production will translate to patterns in the surface.

Most fdm printers might be accurate to .1mm, with the best getting to around .05mm in z and any measurement below that is basically random noise, so you have finite limits on how precise you can get measuring defects.

This means that well tuned printers will generally be close enough that it’s hard to differentiate between them.

Now imagine a pattern in an introduced by a warped lead screw, as an example. Sure this is cyclic. But its height is dependent on the lead screw’s thread lead. A T8x8 has an 8mm lead and this pattern will repeat every 8mm in height, with a consistent layer count between them.

As will basically every printer using a t8x8 screw. Printing at that same layer thickness. Which is pretty much every printer on the market. There might be some slop with backlash, but that’s not going to show up accurately enough.

And yes. You can swap out nozzles, just like you can belts and lead screws and every other part. Unlike most parts, though, the microscopic striations coming off the nozzle aren’t as inconsistent as say belt tightness.

I’m rather skeptical as well, but if there’s a defect on the nozzle causing stations in the extrusion, that might do it.

Otherwise they might get lucky, but I doubt it.

Resin printers might have something else, but it’s hard to imagine what. (Maybe dead pixels?)

I don’t. Fdm printing has very small cracks at the layer lines. It wouldn’t be quite as bad as say, something with food, or for a close shave rather than a trim, but bacteria will grow in it.

Fdm cannot be reasonably sterilized. Resin printers are better, but not perfect. Even if it doesn’t cause infections, it’s going to pick up an odor.

I use a muhle (they sell them on the link.) I’d suggest starting with a closed comb head and whatever handle suits you. (They’re interchangeable,)

I use an open comb and it’s much more aggressive, and not for starting out.

I’d recommend staying away from the frequently recommended “entry” razor- the Merkur 34c. The head on the one I tried has a ridiculous amount of play in how it held the blade- it’d clamp down but it’d never consistently seat itself so it was always off center or twisted.

As for blades, I use feather, but you can buy variety packs and find the set that works for you. That tends to be the most variable part.

All I really known about it is that you can roast pot in butter and extract the thc/cbd into the butter then use that to make cookies.

But yes.

I also know that you need to be careful to keep them sorted from normal cookies. Don’t, ah, ask how I know that.

“Magic Cookie” is the term I use for cookies baked with cannabutter.

This could also be caused by belts being too tight, as they may cause motors to skip steps.

Probably loose belts, but it’s important to not have them too tight. They should be snug, but you should also be able to squeeze and flex the belts without a lot of effort.

Is this one of the “team building” songs they make you sing at MS?

“You pay me to do what I do, so you don’t have to worry about it.”

simple. fire the asshole.

yeah, that’s pretty messed up. you should never cross spiders with teddy bears.

and that is why standard sizes exist. The solution then, is to get every one on standardized sizing so the parts work.

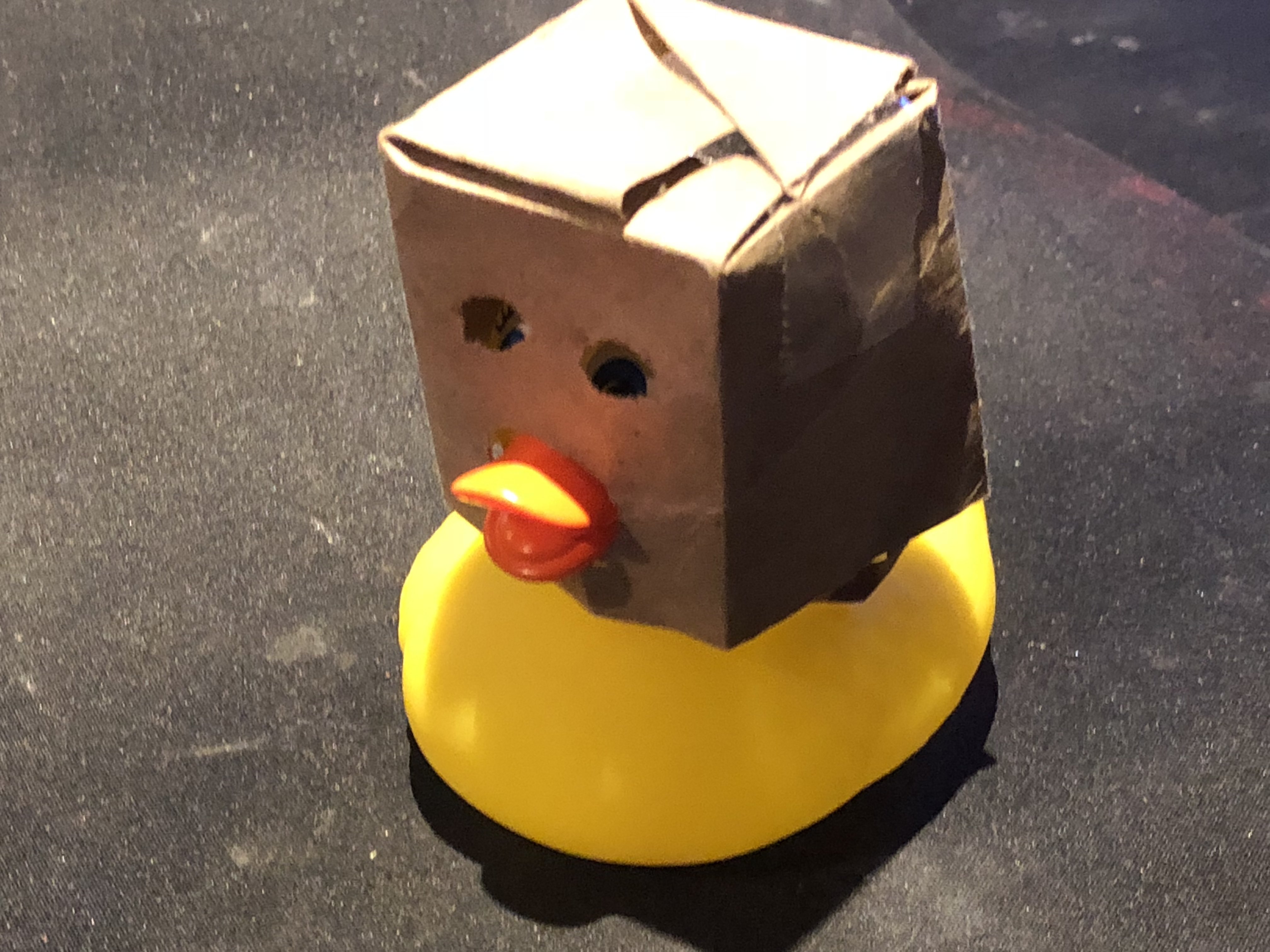

The problems are that now somebody needs to have and maintain a printer. (I presume FDM, but resin or something would be more useful.) even then, the production is limited, and you’re still having to source filament or whatever, as well as the parts necessary to maintain it. These parts are all more complicated than PVC pipe fittings are. (and depending on where we’re talking, may not even be available for a variety of reasons.)

and when the part fails (as all things eventually do,) you’re going to be right back where you started. You might be able to get another custom part printed. if the guy happens to still be around and availible.

Granted, the people running the study or setting up the open source fittings probably don’t have the money to encourage people to replace their plumbing, but that’s the solution that won’t see us right back at the problem in a few years. or less.

this is probably more for things that people won’t bother stealing. I certainly wouldn’t be trusting my phone to it.

I’d also be worried about it getting covered and misplaced/lost. piles of sand look much like another.

Could be a fun geocaching thingamabob, though.

Edit: I’d also suggest sticking a silicone o-ring on the lid. you can make them pretty easily using fish tank air-hose tubing. Pump it full of calk. If you want a solid ring, let it cure, then blow it out with an air-blower nozzle on an air compressor. If you want a hollow ring, which for this would be best, I think; blow out the tubing before it sets. then blow it out again. cut the ends on a bias and then glue them with more calk.

For this, you’d never know when a kid comes running over with a giant pale of water.